In this episode, host Kristin Hayes talks with Jeffrey Rissman, the industry program director and head of modeling at Energy Innovation, a climate policy firm focused on accelerating decarbonization. Rissman discusses a journal article he coauthored with 29 other researchers, which assesses strategies for propelling decarbonization of industry. According to Rissman, the industrial sector is vast, diverse, and difficult to regulate—but deep decarbonization is nevertheless possible, if ambitious policies are implemented and transformative technologies are deployed.

Listen to the Podcast

Notable Quotes

- Decarbonizing doesn’t have to be disruptive to industry: “You may think it would be very expensive to replace and upgrade all of that equipment right away. But remember that machinery doesn't last forever. Machines grow old, they break down, or they just become obsolete, and just about all of it is going to be replaced, anyway, within the next 50 years. So, as long as we ensure that new machinery being purchased today and onward uses clean energy … then we can transition this huge installed base of equipment in accordance with its natural turnover cycles and avoid excess replacement cost.” (9:59)

- Policy shifts can help decarbonize industry: “To fully decarbonize industry requires smart, ambitious policy. That means that policymakers in a variety of countries need to recognize the importance of moving to clean energy and to enact policies to help accelerate that transition … I think that companies are going to find it to be an increasing liability, to be inefficient and highly polluting in the twenty-first century, as more and more attention is paid to the climate change crisis.” (11:22)

- Carbon pricing highlights the costs of carbon pollution: “Existing fossil fuel combustion benefits from not having to pay for all of the damage it's doing—and that's not just damages to climate. We have many thousands of Americans dying in the United States every year due to air pollution caused by fossil fuel combustion. Those are costs that are borne by the people who get sick and who die, and not by the folks who are burning or producing the fuels that are causing these public health damages. So, a carbon price properly set would reflect not just damages to the climate, which will harm human society, but also direct public health damages.” (28:39)

Top of the Stack

- "Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070" by Jeffrey Rissman, Chris Bataille, Eric Masanet, Nate Aden, William R. Morrow III, Nan Zhou, Neal Elliott, Rebecca Dell, Niko Heeren, Brigitta Huckestein, Joe Cresko, Sabbie Miller, Joyashree Roy, Paul Fennel, Betty Cremmins, Thomas Koch Blank, David Hone, Ellen D. Williams, Stephane de la Rue du Can, Bill Sisson, Mike Williams, John Katzenberger, Dallas Burtraw, Girish Sethi, He Ping, David Danielson, Hongyou Lu, Tom Lorber, Jens Dinkel, and Jonas Helseth

- "Energy Policy Simulator" from Energy Innovation

- Sustainable Materials without the Hot Air by Julian M. Allwood and Jonathan M. Cullen

The Full Transcript

Kristin Hayes: Welcome to Resources Radio, a weekly podcast from Resources for the Future. I'm your host, Kristin Hayes. This week, I'm talking with Jeffrey Rissman, the Industry Program Director and Head of Modeling at Energy Innovation, a research firm focused on accelerating clean energy. Jeff leads modeling efforts for the firm's energy policy solutions focus area to determine the policies that most effectively help meet climate and energy goals. Jeff is the lead author on a new paper recently released and published in the journal Applied Energy that dives deep into the technologies and policies that might drive decarbonization across global industry.

The industry sector is notoriously difficult to decarbonize, but it's critical to meeting long-term emissions reduction goals, and Jeff is going to talk us through what he and his coauthors learned about the opportunities and the challenges. Stay with us. Jeff, thank you so much for joining us on Resources Radio. It's really nice to have you with us.

Jeffrey Rissman: Hi, Kristin. Thank you so much for having me on the show.

Kristin Hayes: Yes, yes. I'm really looking forward to our discussion today, but before we dive into the meat of today's conversation, I wondered if you could tell us just a little bit more about your own background and how you started working on clean technology issues.

Jeffrey Rissman: Sure. I'd be happy to share a bit about my background. So I've been working with Energy Innovation since the firm was founded in February of 2012. I've worn a number of hats, but my first big project was working on innovation policy. That is how government policies and programs can accelerate research and development of clean energy and efficiency technologies. I produced a report based on interviews with chief technology officers and chief scientists at 16 innovation-oriented companies like Microsoft, Ford, Boeing, and BP. But most of my time at Energy Innovation has been spent on the Energy Policy Simulator.

I'm the lead developer of that computer model. It's a free and open source tool that can estimate the impact of numerous energy and environmental policies on pollutant emissions, financial costs and savings, electricity generation, electric vehicles, public health, and more. We've worked with partners worldwide to produce versions for 11 countries and regions now, with more to come. Your listeners might enjoy trying it out. It's available online at www.energypolicy.solutions.

Kristin Hayes: Okay. Well, we'll try to embed a link to that in the podcast webpage as well, so that our listeners will have access to that link. Given what I know about the audience that generally engages with RFF, they will love to play around with something like that. So, yeah, one last question before we kind of dive in and really talk about what you and your coauthors learned: I wanted to start with a somewhat unusual question, although I promise it has a purpose, but this particular paper has more coauthors than any other paper I've seen, 30 people in total. So, I wanted to ask, what does that tell us about what you all were trying to accomplish with this research?

Jeffrey Rissman: A good question. It is a lot of coauthors. So, in this research, our goal was to identify a technology and policy pathway by which society can reduce global industrial greenhouse gas emissions to zero. So, as you can imagine, that's a big topic. There are many industries out there and they are producing all of the manufactured materials and products that we rely on every day, and such a big problem can best be solved by bringing together lots of different expertise. So, some of our authors are experts in particular industries, such as chemicals and plastics, or cement and concrete, whereas some have deeply studied particular types of policy like energy efficiency standards, or carbon pricing, or innovation policy.

We also have geographic diversity and authors from many of the top countries in terms of industrial production, including China, the United States, India, and Germany. That helps give our study a broad perspective and ensure it covers all of the major industries, the key technologies, and the policies that can help ensure that those technologies are commercialized and deployed at scale around the world.

Kristin Hayes: You and your coauthors do a very good job of showing the complexity and the breadth of things that you need to be thinking about when trying to tackle this issue. So, it struck me that that was represented in the number of perspectives that were brought to bear and putting it together. So, I wondered if you could give us just a little bit more detail on what the industrial sector means in this case. You mentioned a few of the industries, but can you give us a little bit broader context on what the definition of the industrial sector is? Also, what types of greenhouse gas emissions that sector is in fact responsible for?

Jeffrey Rissman: Absolutely. So, in our study, we considered all manufacturing activities to be part of the industry sector. So, globally the largest three are the iron and steel industry, the chemicals and plastics industry, and the cement and concrete industry. Some other big ones include petroleum refining, manufacturing of machinery, the pulp and paper industry, and ceramics—that is primarily brick and tile. Sometimes, it's easier to envision if you also understand what's excluded.

So, we don't consider agriculture or waste management that is water treatment, or landfills, or natural resource extraction, meaning activities like coal mining or oil and gas drilling to be part of the industry sector in this study. Similarly, emissions from vehicles used to transport the input materials to factories or to transport the produced goods away, that's considered part of the transportation sector, not the industry sector.

Kristin Hayes: Right. Okay.

Jeffrey Rissman: So, the second part of your question was about the types of emissions that industry produces. I like to think of that as divided into three broad categories. So, first, there are direct energy-related emissions. Those come from industrial facilities that burn fuel, such as coal or natural gas, inside the facility itself to generate heat or power. For example, to heat boilers, or to melt the input materials they're working with. The second type of emissions from industry are process emissions. So, those would be greenhouse gases that are produced as a product or byproduct of manufacturing processes.

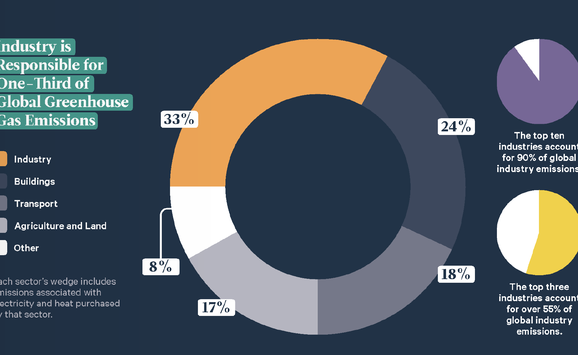

So, a good example of that is in the cement industry, where some of the carbon dioxide they produce comes from chemically breaking down limestone to produce a substance called clinker. Clinker is the main ingredient in cement. Then, the third category that I think of are the indirect emissions that are associated with the generation of electricity that's purchased by industrial facilities. So, those emissions actually occur in the electricity sector, but they're due to the industrial electricity demand. To give a sense of scale, if you include all three of these types of emissions, industry is responsible for one third of global greenhouse gas emissions.

If you exclude the indirect emissions, you say that's part of the electricity sector, then industry is still responsible for about one fifth of global emissions.

Kristin Hayes: Yeah, and I think that's one of the reasons that ... It seems like the industry sector has gotten more attention in recent years as policymakers recognize that given the magnitude of the emissions that are coming out of that sector, there needs to be concerted effort given to thinking about how to decarbonize it. I just wanted to reflect that the very first line of the abstract for the paper notes that fully decarbonizing global industry is essential to achieving climate stabilization. I want to home in with you for just a second on that word ‘fully.’

Because my understanding is that this is a sector that can be notoriously challenging to decarbonize. Feel free to correct me if that's not the case, but I wanted to talk to you about some of the challenges that you see in reaching these decarbonization goals and particularly these ‘full’ decarbonization goals.

Jeffrey Rissman: That's right, Kristin. It is challenging to fully decarbonize industry, but it is important. Fully decarbonizing industry means no net greenhouse gas emissions, that is, they emit no more than they store. I think there are a few reasons why it's challenging. First, industry is vast. There's just a tremendous amount of installed manufacturing equipment around the world. Most of which is powered by fossil fuels or fossil fuel-generated electricity. But I want to include some solutions along with these challenges because that's important too.

So, you may think it would be very expensive to replace and upgrade all of that equipment right away. But remember that machinery doesn't last forever. Machines grow old, they break down, or they just become obsolete, and just about all of it is going to be replaced anyway, within the next 50 years. So, as long as we ensure that new machinery being purchased today and onward uses clean energy, or at least has a pathway to do so, without requiring replacement of the machinery, then we can transition this huge installed base of equipment in accordance with its natural turnover cycles and avoid excess replacement cost.

The second challenge is that industry is diverse. So, there are millions of companies producing countless different types of products. At first glance, that might make it seem technically difficult to come up with so many different solutions, but fortunately, unique solutions for every product line or even every industry are not required. There are strategies such as electrification and the use of hydrogen or hydrogen-derived fuels that can deliver zero carbon energy and high heat in a form that can be used by numerous different industries. The third challenge I'll highlight is that industry is spread among many different countries.

So, to fully decarbonize industry requires smart ambitious policy. That means that policymakers in a variety of countries need to recognize the importance of moving to clean energy and to enact policies to help accelerate that transition. Fortunately, that can be done either through some level of international cooperation but also through national self-interest. Since a lot of the improvements involved here, such as efficiency improvements, are going to be beneficial to a country's industrial sector.

I think that companies are going to find it to be an increasing liability, to be inefficient and highly polluting in the twenty-first century as more and more attention is paid to the climate change crisis.

Kristin Hayes: Yeah, and Jeff, that raises just one additional question for me. Are there good forums that you know of where countries can in fact share best practices related to the technologies? We'll talk about a few of those in more detail in just a second, but you raised a really good point—that part of this requires everyone on board, and I wondered what the opportunities are for cross-country collaboration on this particular issue.

Jeffrey Rissman: Good question. I'm not an expert in the available international forums although I will point out that many of the companies we're talking about are themselves multinational.

Kristin Hayes: Mm-hmm (affirmative). Yeah, good point.

Jeffrey Rissman: So, anything that a large multinational chemicals company learns from research done in one country, they can apply that technology—those learnings—throughout their supply chain, in whichever countries they operate in. Then, their competitors might feel pressure to do the same in order to keep up and remain competitive. So, to some degree, I think it may not be as difficult to lift as it seems, because some of it may diffuse naturally through the multinational structure of companies and competition.

But also, I think there is a role for developed countries to provide technical expertise and support to developing countries in particular, where a lot of the goods that the developed countries buy are made. China, for example, produces more industrial goods than any country in the world. We—I'm based in the US—import goods from numerous countries that are still developing: India, Vietnam and so on. So, I think there's a role there for technical assistance where policymakers, through national laboratories or other forums like that, can engage in cooperative R&D agreements, and technology sharing with similar organizations in other countries.

Kristin Hayes: Great. Thank you for reflecting on that. So, let's talk in more detail about some of the technologies that you and your coauthors suggest might play a role in decarbonizing the industry sector. You mentioned hydrogen, that's one of the first ones that you call out in the paper, and specifically, renewable electricity-sourced hydrogen. You also call out carbon capture and storage. So, I wondered if you can say a bit more about how industries might use these technologies in their decarbonization efforts.

Jeffrey Rissman: Certainly. So, while burning fossil fuels like coal or natural gas produces carbon dioxide, CO2, that's the most important greenhouse gas, hydrogen gas doesn't contain any carbon atoms. Its chemical formula is H2. Burning it produces only water vapor. So, why burn something at all? Well, many industrial processes rely on high heat. For example, the iron and steel industry needs to be able to melt metals, and the cement industry needs high temperatures to form clinker. In many industrial processes, it's easier to obtain that high heat through chemical combustion rather than by using electricity directly.

That's why industry benefits from a zero carbon chemical fuel that it can burn. Today, most hydrogen is produced by steam reforming of methane, which produces CO2. In China, it's often produced from coal, but hydrogen can also be obtained by using electricity to split water—that is H2O—into oxygen and hydrogen. If that electricity comes from a zero carbon source such as wind or solar power, then that method of producing hydrogen will involve no CO2 emissions. That makes hydrogen a promising zero carbon fuel for industry.

It's also an important chemical feedstock for the chemicals industry, and it can be converted into other chemicals, such as ammonia or methane, with a modest energy penalty, which would allow you to use the fuels in industrial equipment that isn't able to burn hydrogen directly. That would be good in a sort of transition period before hydrogen-burning equipment rolls out fully. The other technology you mentioned is carbon capture and storage, or CCS. So, while improving energy efficiency and switching to clean energy is often more economical and generally should be done first, there are some CO2 emissions that may be difficult to abate that way.

A good example would be the processed CO2 from the cement industry I mentioned earlier. CCS may be the best solution for these last difficult to eliminate industrial CO2 emissions. CCS essentially means extracting CO2 from a waste gas stream and storing it underground or in products called ‘carbon capture and use.’ Energy is typically needed to recharge the chemical materials that are used to capture the CO2. So, CCS increases the energy requirements of the industrial processes. More research and development will be needed to drive down the costs and improve the efficiency of both zero carbon hydrogen production and CCS technologies.

Kristin Hayes: Yeah, I think I will admit that the conversation around hydrogen in particular is one that I feel like is only in the past several years really come onto my radar. But your description and a few other things I've read sort of really helped illustrate why that technology, which I think is relatively under the radar, at least in a public sense, has huge potential. So, Jeff, you call out a number of other supply side and demand side changes that various industries might make, and the paper is so rich and full of content.

There are more of those than we can really cover in depth on this particular podcast. So, maybe I wanted to ask you if you can highlight a few for us that look most promising to you, and I would invite you to define promising as you see fit. So, whether that's ready for deployment, whether that's likely to be cost effective, whether that's productive across a range of industries, as you pointed out earlier. So, if you're comfortable, could you share a few of the most promising with us?

Jeffrey Rissman: Absolutely. I would agree that all three of those things you mentioned are important criteria for what is the most promising. It has to be able to be rolled out at scale, and soon, and work in a variety of industries, and be cost effective, and so forth. One area I'll highlight since we haven't discussed it yet, and I think it's often overlooked are the demand side interventions. That is, ways to use less material or product while delivering the same or better service that people or businesses care about.

For example, it's possible to build high quality structurally sound buildings that use less concrete than typical buildings today. Techniques can be used to make concrete stronger, such as using tension steel cables, or injecting CO2 during the curing process. Or, you could pour concrete in curve fabric molds that put the material exactly where it's needed. 3D printing is another way to produce quality parts and products using less material, because the printer doesn't waste material as traditional manufacturing techniques like sanding and milling do.

Then, beyond the manufacturing stage, some methods of reducing demand for products include sharing of products and also designing products to make them easier to repair and so they last longer. Then, when they're no longer needed, they can more easily be sold or donated to a new user instead of thrown away. Then, a different promising approach that is technologically mature and ready for large scale deployment is to improve energy efficiency through integrated design. So, today, if you think about energy efficiency in an industrial facility, people have mostly thought about specific components such as efficient electric motors or pumps or boilers.

In modern facilities, these components are often already generally pretty energy efficient. However, there remains a great deal of potential to improve energy efficiency by thinking about the facility as a whole and designing the equipment to optimize material and product flows, and then to right size the equipment for the task. For instance, if a pump is too large and it only runs at half of its design capacity, it's going to be wasting energy relative to a pump that's correctly sized for the load that it's pumping.

Kristin Hayes: So, Jeff, I always find the questions about energy efficiency innovations in particular fascinating because there's an implication, and again, please feel free to correct me if this isn't a fair assessment. But there's an implication that these are things that industry could be doing now that would lead to efficiency gains now. Yet, those business decisions aren't currently being made. So, is there any reflection that you have on why those things that would seem to be sort of naturally cost-effective on their own, regardless of a particular focus on climate or CO2 emissions reductions, why they wouldn't be happening already?

Jeffrey Rissman: Yes. We actually have a section of the paper exactly on that question.

Kristin Hayes: I set you up really well.

Jeffrey Rissman: That's right. It does seem counterintuitive at first that industries would not already invest in anything and everything that is cost effective, and energy efficiency is cost effective, but there's a number of barriers that can happen. One is that energy tends to be a small percentage of a firm's total costs. So, a manufacturing firm is going to see most of its costs in buying its input materials or parts. Then, also its labor costs and its facilities, like renting or buying land and manufacturing facilities and what not.

So, when they're looking at business decisions, given a limited amount of attention and time that executives can pay on deciding what projects to do and how to assign them to staff and project managers, and basically a limited capacity to get things done, the business is going to be looking to optimize profit and revenue overall rather than looking for the highest percentage return things. So, even if an energy efficiency upgrade achieves a phenomenal percentage return, it's a percent of a small base.

So, it may not quite make the cut in terms of importance as far as what the industry wants to spend their time working on. So, it's just not as much on the radar of a lot of industrial firms as it could be.

Kristin Hayes: Yeah. What I was thinking about as you were saying that is that, what is particularly helpful to compliment the individual business decisions is in fact a policy framework that indicates where the long-term commitment to decarbonization lies. That's something that you and your coauthors call out very explicitly in the paper as well. The paper describes not only the role that technology improvements can play, but the role for policy. I wanted to pivot there for just a minute and ask you to say a little bit more about the policy drivers that you and your coauthors called out as being particularly valuable.

Jeffrey Rissman: Absolutely. So, policy is extremely important here, and policy determines a good part of the environment that industrial firms see when they decide to make investment decisions in manufacturing capabilities or technologies and whatnot. In policy, there are a number of policies that can help industries along and accelerate this transition and make it more cost effective to make the investments that are needed in order to bring these new cleaner technologies to scale. So, the top three that I'll highlight from the paper are support for research and development, carbon pricing, and energy or emissions standards.

Kristin Hayes: Okay.

Jeffrey Rissman: So, R&D support looks like things like properly funding national laboratories and having the national labs partner with industries in order to develop newer, better technologies. Often an industry can't justify the cost to build an enormous national lab scale facility and staff it with supremely talented engineers and scientists just to answer a specific research question for their product line. But they can afford to partner with the national lab and use those facilities and the staff expertise that's already there.

There are other ways government can support R&D. They can fund it directly or through R&D tax credits. They can establish institutes that help with the commercialization of new technologies. Sometimes, there's a bit of a funding gap that can help technologies go from the laboratory to commercial scale in the United States, ARPA-E, the Advanced Research Projects Agency for Energy is one organization that tries to help newer companies and ideas get over that hump and reach commercialization. Then, there's a dimension for talent.

So, having good science technology, engineering, and mathematics education programs, or government-funded internships for top engineering students to work in companies. Immigration policy, making it easy for degree holders in relevant science technology, engineering, mathematics fields to get green cards—that is, permanent residency cards—and citizenship, and so on, helps companies have the talent they need to do the R&D here instead of pushing it into other countries where those countries would then benefit.

Kristin Hayes: Jeff, you just enumerated for us a number of ways to increase support for R&D. What can you tell us about the other two broad policy types?

Jeffrey Rissman: Sure. So, the carbon pricing and the emissions or energy standards are the other two. Carbon pricing is a very important policy intervention for industry. So, carbon pricing, how effective it is varies by sector, depending on how sensitive that sector is to price signals. So, in certain sectors where there is low elasticity, that means low sensitivity to fuel prices, carbon pricing can be not very effective. Industry, fortunately, is one of the sectors where carbon pricing actually is a better fit, and industries do pay attention to their input cost.

I think it's too technical to get into the minutia of carbon pricing design here. I will say that on an economic justification level, that this is really about leveling the playing field. So, existing fossil fuel combustion benefits from not having to pay for all of the damages it's doing, and that's not just damages to climate. We have many thousands of Americans dying in the United States every year due to air pollution caused by fossil fuel combustion. Those are costs that are borne by the people who get sick and who die, and not by the folks who are burning or producing the fuels that are causing these public health damages.

So, a carbon price properly set would reflect not just damages to the climate, which will harm human society, but also direct public health damages. I think that if these damages were reflected in the price of fuels, that's fair. That's what a level playing field is. That would make a lot of these fuels look far more expensive than they are today because those costs, which we are paying today, are just hidden. They're being borne by other people like the unfortunate folks who are getting sick.

Kristin Hayes: My economist colleagues would be thrilled to hear you talk about externalities and carbon pricing. I would suggest that if anyone does want more details, there are plenty of those to go around on RFF’s website. But certainly, that's an instrument that is, it's good to hear that the industry sector is in fact a sector that would be responsive to a carbon price, and that that could be a valuable instrument in sort of driving decarbonization there.

Jeffrey Rissman: Definitely. Then, on the topic of standards, those are valuable, too. So, an emission standard should be technology-neutral, and it should be based on the amount and type of product that's produced. So, if you impose standards on how much energy or emissions specifically can be produced per ton of a given type of steel or per ton of raw ammonia, that will give companies an incentive to innovate. So, it will help them find ways to produce the material with less emissions. One good way to ensure that standards don't stagnate and become ineffective, but also are achievable, is to build in automatic improvement based on the best products that are already in the market, or the best industrial processes that are already in the market.

By setting it based on something that's already in the market and not just the top 1 percent or something, but a significant share, like the top 40 or 50 percent, you ensure that this is possible. This is something industry can do. It's been demonstrated. It's been commercialized at large scale. It is totally doable at reasonable cost. Then, by continually updating it every three years later, you take the top 50 percent again, and again, and again, you're driving innovation forward in line with the rate at which the industry is able to improve its production processes.

So, then, you don't have to worry about whether an agency in the government or a legislature is going to step up and tighten the standard because there's a formula to do it automatically, and that provides a little bit of political protection as well.

Kristin Hayes: Interesting. Well, Jeff, thank you for talking us through the findings of this, again, incredibly rich paper. Any sort of closing thoughts on that particular topic?

Jeffrey Rissman: Yeah. I would say that the big takeaways for me are that no technology and no policy is a silver bullet. We need a mix of interventions in order to decarbonize global industry. It's crucial to get started on research and development now to help refine the existing technologies and prepare new ones. It's critical to get started on deployment now, so that we begin bringing emissions down right away.

Kristin Hayes: Great. Yeah, and this is definitely a sector to keep an eye on, and it's wonderful to have such a diverse set of experts coming together to shed some light on these important issues. So, I will close with our usual feature called Top of the Stack. This is where we ask our guests to share with our listeners something that you found particularly compelling either in written form, or another podcast, or a video. Anything that might be on the top of your stack that you'd recommend.

It can be on the specific topic of industrial emissions, or it could be more broadly about clean energy. Anything that you think might be of interest to our listeners. What's on the top of your stack, Jeff?

Jeffrey Rissman: Sure. Well, if any of your listeners would like to delve a little more deeply into the topic of industry and in particular on reducing material use, I recommend the book Sustainable Materials Without The Hot Air by Julian Allwood and Jonathan Cullen.

Kristin Hayes: Good title.

Jeffrey Rissman: I've found it to be just an excellent resource on how to make buildings and products with less material, and it's illustrated and quite readable.

Kristin Hayes: Great.

Jeffrey Rissman: Also, I really think your listeners would enjoy trying out the Energy Policy Simulator, which I mentioned earlier. They can find it at www.energypolicy.solutions.

Kristin Hayes: Fantastic. Well, Jeff, thank you again for talking us through this important piece of research. It's been a pleasure talking to you and I look forward to learning more about the industry sector as time goes on.

Jeffrey Rissman: Thank you, Kristin. It's been a pleasure.

Kristin Hayes: You've been listening to Resources Radio. Thanks for tuning in. If you have a minute, we'd really appreciate you leaving us a rating or a comment on your podcast platform of choice. Also, feel free to send us your suggestions for future episodes. Resources Radio is a podcast from Resources for the Future. RFF is an independent nonprofit research institution in Washington, DC. Our mission is to improve environmental, energy, and natural resource decisions through impartial economic research and policy engagement.

Learn more about us rff.org. The views expressed on this podcast are solely those of the participants. They do not necessarily represent the views of Resources for the Future, which does not take institutional positions on public policies. Resources Radio is produced by Elizabeth Wason, with music by Daniel Raimi. Join us next week for another episode.